-

Solids Control System for Drilling Mud System

TR Solid Control has a professional team to provide customers with professional drilling mud treatment solutions and the most favorable delivery terms. our solids control system is an essential investment for any drilling operation looking to optimize performance and efficiency while reducing costs. With our cutting-edge technology and professional team, we offer unparalleled support, service, and delivery terms to ensure our customers receive the best possible experience. Contact TR Solids Control today to learn more about our industry-leading solids control system and how it can elevate your drilling operations to new heights of success.

-

Introducing the Drilling Mud Hopper

The Mixing Hopper is equipped with a unique combination of venturi and original nozzle, which simplifies the mixing process while providing the best mixing results. Drilling mud hopper has simple structure and strong feasibility, which is an ideal choice for fast and uniform mixing of drilling fluid and its additives. One of the main advantages of the Drilling Mud Hopper is its ability to achieve the best possible mix with the least amount of waste.

-

Swivel Type Mud Gun is used in Mud Tank

Mud Gun is used in solids control system mud tank. TR solids control is Swivel Type mud gun manufacturer.

Mud Gun is a part of the mud cleaning process and is designed to be used in solid control systems. Swivel Type Mud Gun is used to provide primary mixing inside mud tank. The number of mud gun depends on the size of tank. Swivel Type Mud Gun is divided into three – low, medium, and high pressure.

Mud Gun is a part of the mud cleaning process and is designed to be used in solid control systems. It is a tool that is primarily utilized for the purpose of mixing drilling mud while ensuring that the mud does not precipitate. Swivel Type Mud Gun is made with high-quality standard steel, with the nozzles being from polyurethane and tungsten carbide alloy. It is a simple but highly useful tool in the solid control system. The equipment is easy to operate while also being flexible in nature. Swivel Type Mud Gun is divided into three – low, medium, and high pressure.

-

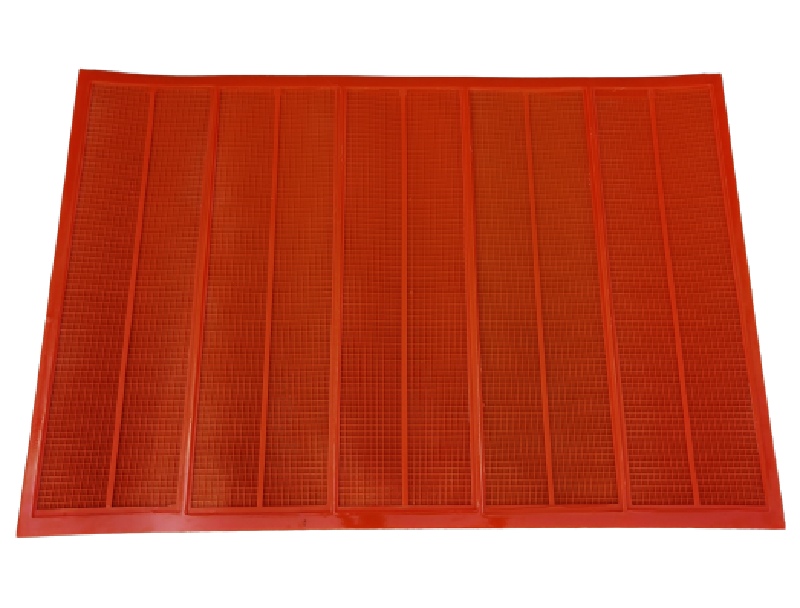

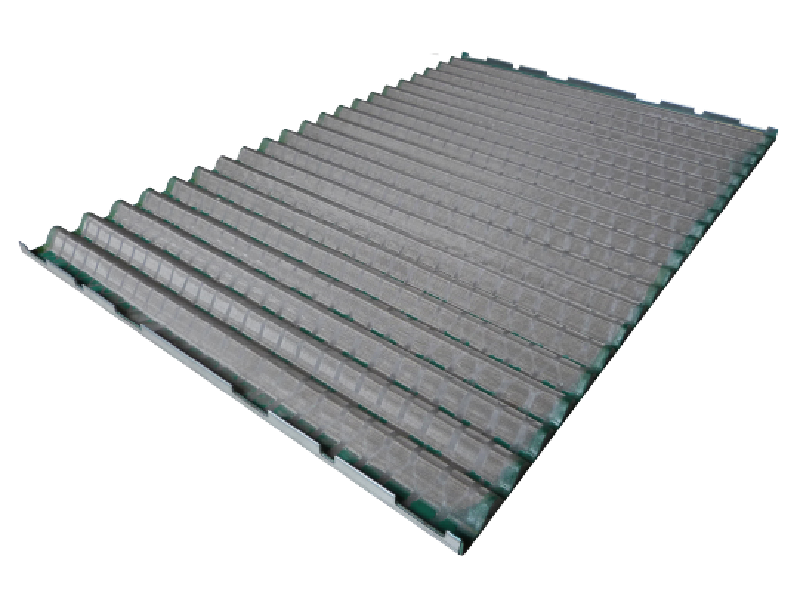

TH48-30 x 0.1MT Urethane Panel Screen

Urethane Panel Screen Kind of Polyurethane Fine Screen . Urethane Panel Screen is designed for the replacement screen of Derrick Stack Sizer.

TH48-30 x 0.1MT 1040×700 Urethane Panel screen is made of polyurethane sheet with high quality screen surface.

• Screen material: polyurethane (PU).

• Hole shape: round, square, rectangular. (or upon request).

• Types: polyurethane fine screen mesh, tensioned polyurethane screen, modular polyurethane screen, steel core polyurethane screen.

• Size: customized design.

• Color: red, yellow, green, etc. -

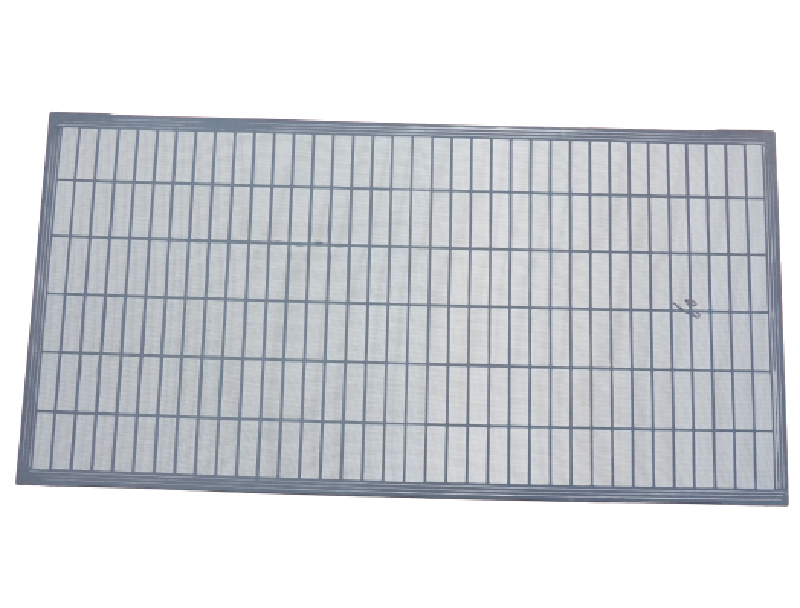

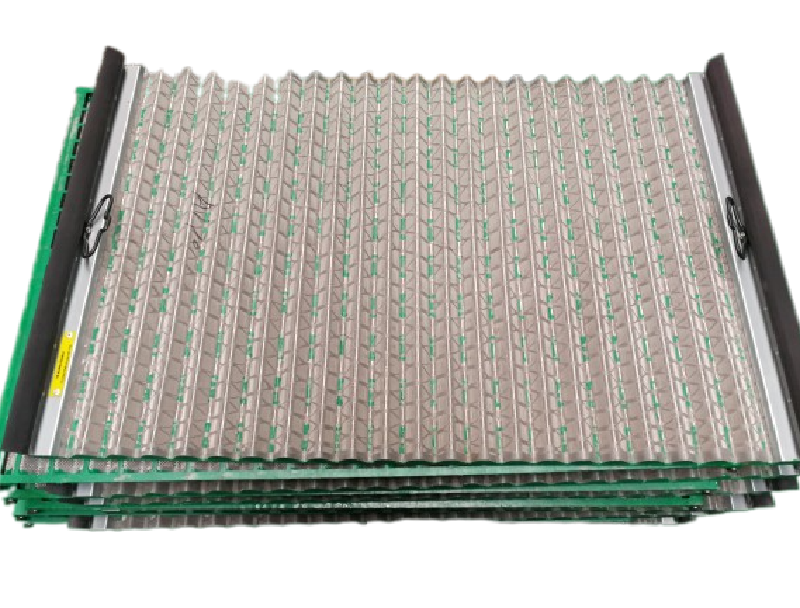

Mongoose Screen for Swaco Mongoose Pro Shaker

Mongoose Screen is designed for the replacement screen of Mongoose Pro Shaker Screen. TR is a SWACO Screen manufacturer and China Mongoose Screen supplier .

Replacement Mongoose Screen have steel and PT frame types for your choice. Swaco mongoose pro shaker screen size is imperative in ensuring a job well done for mud flowing over the shale shakers.

Technical Parameter

• Mesh Material: stainless steel 304/316/316 L.

• Frame Material: Q235 steel/PT.

• Screen Type: XL, XR, HC, MG.

• API RP 13C Designation: API 20 – API 325.

• Package: packed in paper carton, shipped by wooden case. -

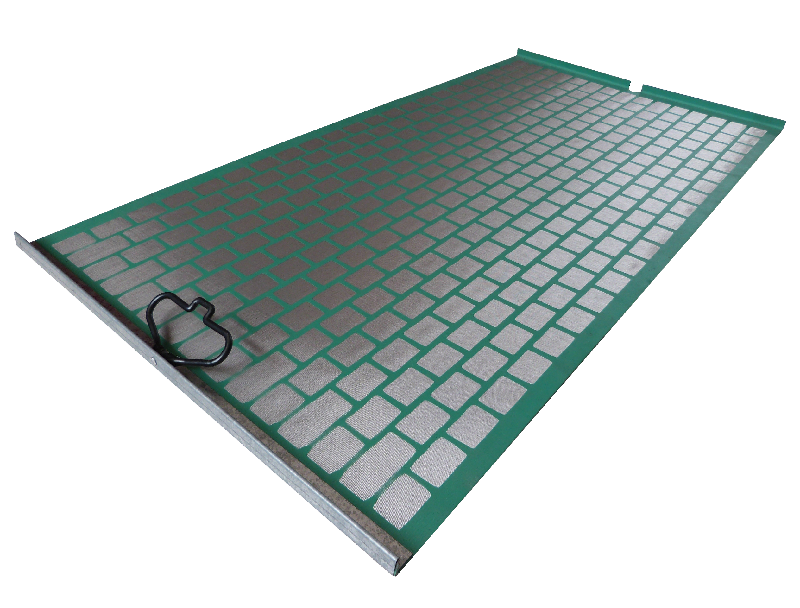

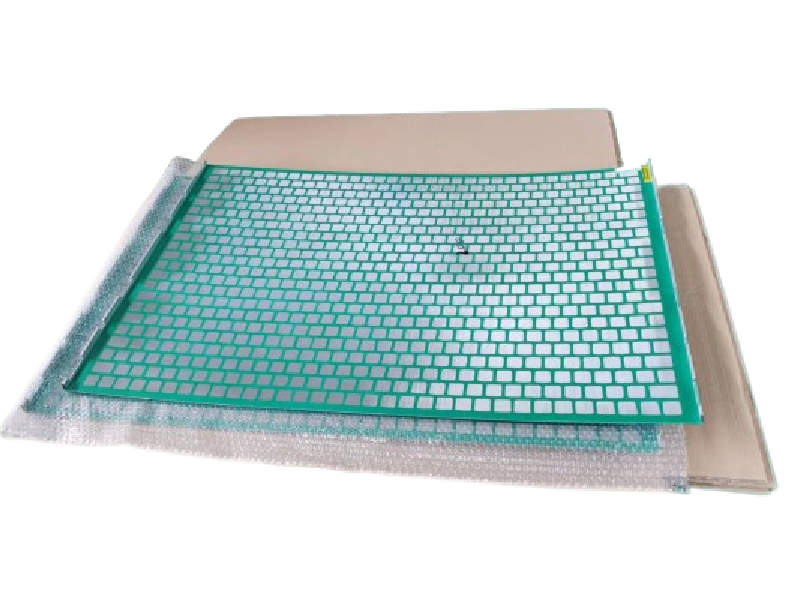

Hyperpool PWP Screen for Derrick Hyperpool Shakers

Hyperpool PWP Screen is designed for the replacement screen of Derrick Hyperpool Shakers. TR is a Hyperpool Screen manufacturer and China Hyperpool PWP Screen supplier.

Technical Paramete

• Material: stainless steel 304/316/316 L.

• Construction Type: PWP (perforated wear plate).

• Wear Mesh Shape: rectangle.

• API RP 13C Designation: API 20 – API 325.

• Series: DX, DF, HP optional.

• Color: green.

• Package: 2 pcs per carton, 20 pcs/wooden case. -

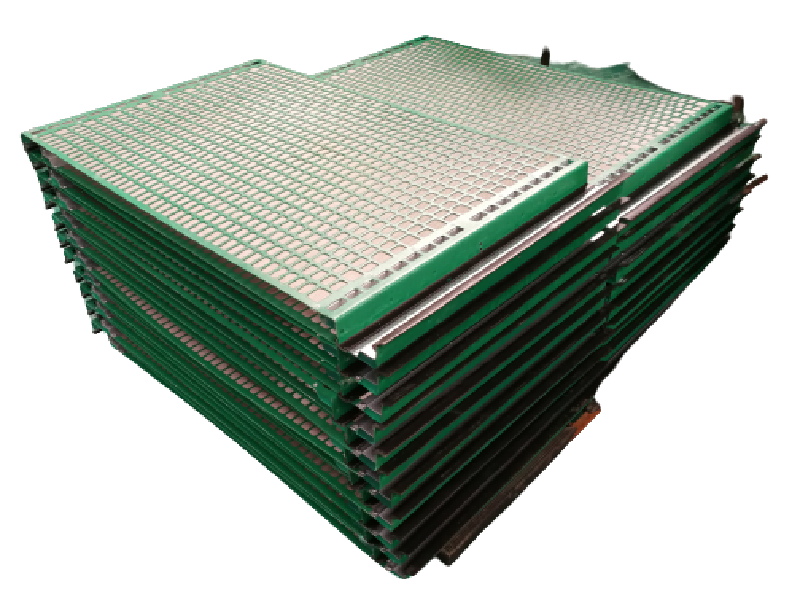

Hyperpool PMD Screen for Derrick Hyperpool Shakers

Hyperpool PMD Screen is designed for the replacement screen of Derrick Hyperpool Shakers. TR is a Derrick Hyperpool Screens manufacturer and China PMD HYP Screen supplier .

Hyperpool PMD Screen is also known as PMD HYP Screen

Technical Parameter

• Material: stainless steel 304/316/316 L.

• Construction Type: PMD (perforated wear plate).

• Wear Mesh Shape: rectangle.

• API RP 13C Designation: API 20 – API 325.

• Series: DX, DF, HP optional.

• Color: green.

• Package: 2 pcs per carton, 20 pcs/wooden case. -

FLC 500 PWP Shaker Screens for DERRICK Shakers

FLC 500 flat shaker screen is designed for the replacement screen of Derrick FLC 500 series shale shakers. TR is a FLC 500 PWP Shaker Screen manufacturer and China Flat Shaker Screen supplier.

FLC 500 PWP Shaker Screen is constructed with two or three layers of 304 or 316 stainless steel wire mesh cloth, and then combined together with a steel backing plate. The FLC 500 PWP Shaker Screen features a single side quick-lock tension system that reduces panel replacement time.

-

48 × 30 PMD Shaker Screens for FLC 2000

TR 48 × 30 PMD shale shaker screen is manufactured based on the innovated design of FLC 2000 shale shaker screens.

TR 48 × 30 PMD shale shaker screen are used as the substitute screen for:

• FLC (Flo-Line Cleaner) 2000 3-panel shaker.

• FLC (Flo-Line Cleaner) 2000 4-panel shaker.

• 48-30 shale shaker.•

• FLC (Flo-Line Cleaner) 2000 series mud cleaners.

• FLC Plus, FLC with AWD, HI-G dryer. -

FLC 500 PMD Shaker Screens for DERRICK Shakers

Pyramid shaker screen also called three-dimensional shale shaker screen. TR is a FLC 500 PMD Shaker Screen manufacturer and China Pyramid shaker screen supplier .

FLC 500 PMD Shaker Screen is used to Derrick 503 Shale Shaker . Pyramid shaker screen is popular in Saudi Arabia.

FLC 500 PMD Shaker Screens are used as the substitute screen for:

• FLC (Flo-Line Cleaner) 503 shaker.

• FLC (Flo-Line Cleaner) 504 shaker.

• FLC (Flo-Line Cleaner) 503 drying shaker.

• FLC (Flo-Line Cleaner) 504 drying shaker.

• FLC (Flo-Line Cleaner) 513 shaker.

• FLC (Flo-Line Cleaner) 514 shaker.

• FLC (Flo-Line Cleaner) 513 VE (Vapor Extraction).

• FLC (Flo-Line Cleaner) 514 VE (Vapor Extraction). -

48 × 30 PWP Shaker Screens for FLC 2000

TR is a FLC 48 × 30 PWP Shaker Screen manufacturer and China FLC 2000 PWP Shaker Screens supplier . We are an exporter of 48 – 30 PWP Shaker Screen .

FLC 48 × 30 PWP Shaker Screen is used for FLC2000 Shale Shaker. Derrick FLC2000 48-30 PWP screen is very popular in Saudi Arabia . Because Derrick Shale Shaker is very popular in Saudi Arabia.

TR 48 × 30 PWP Shale Shaker Screens are used as the substitute screen for:

• FLC (Flo-Line Cleaner) 2000 3-panel shaker.

• FLC (Flo-Line Cleaner) 2000 4-panel shaker.

• 48-30 shale shaker.

• FLC (Flo-Line Cleaner) 2000 series mud cleaners.

• FLC Plus, FLC with AWD, HI-G dryer. -

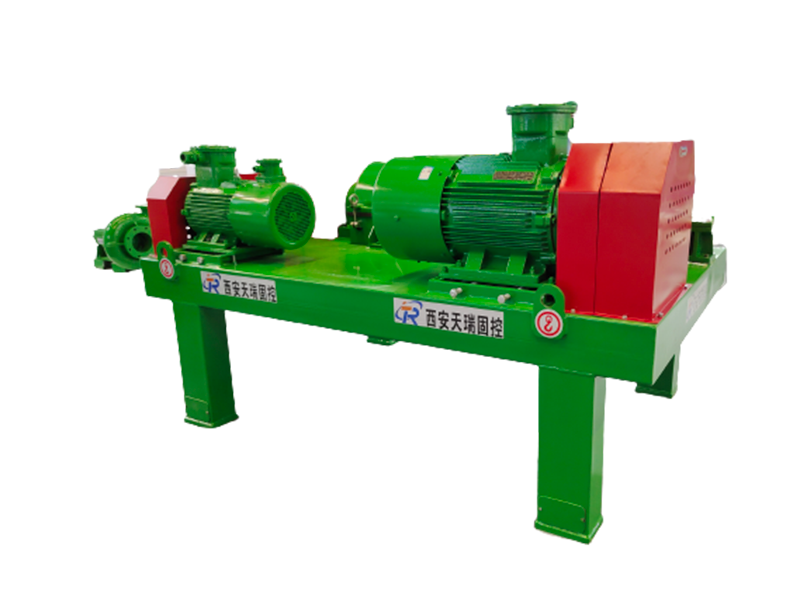

Full Hydraulic Drive Decanter Centrifuge

TR Solids Control is a leading decanter centrifuge manufacturer. And our supplier from Switzerland are leading brand for centrifuge hydraulic driving system. GN and our Switzerland supplier has been jointly working together to develop the full hydraulic drive centrifuge for international clients to meet the highest standard.

The hydraulic bowl and scroll drive system drives both the conveyor and bowl of a decanter centrifuge from hydraulic pump unit by two hydraulic oil circuits.

The advantage of the full hydraulic drive centrifuge is for use in high temperature ambient for heavy mud with flexible bowl and differential speed. The compact one skid design makes it easier for rig up.