Products

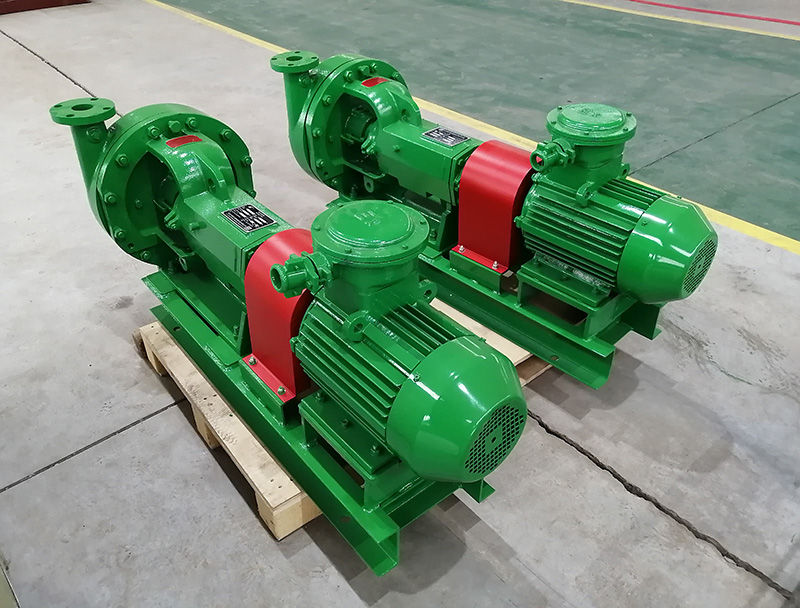

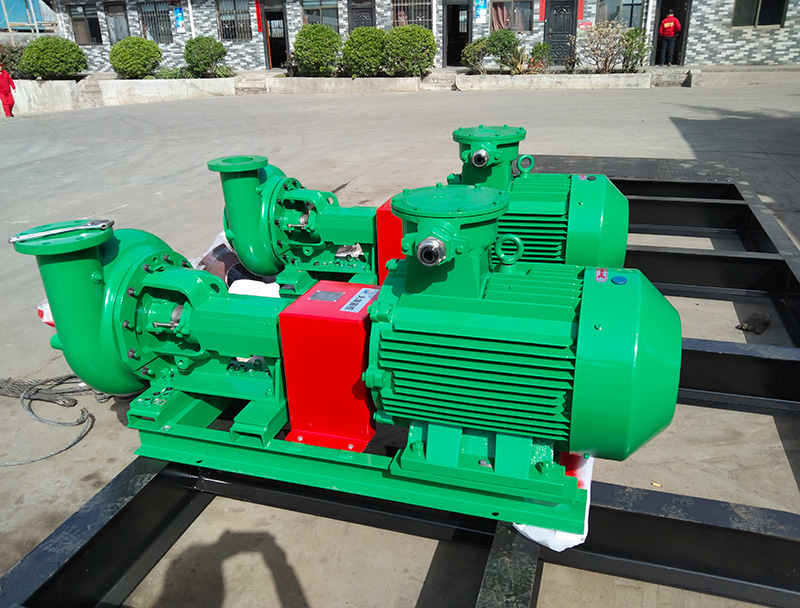

Mud Centrifugal Pump could replace Mission Pump

Features

- Composite Mechanical Seal

The mechanical seal is installed in the inner end of the sealing box, the auxiliary packing seal mounted in the outer end. The double sealing makes the sealing more reliable. - Impeller with Open Vane Structure

The open vane structure impeller reduces the shaft load to minimum, run more smoothly and perform more efficiently. - Higher Output and Efficiency

The vane profile complying with the hydraulic principle, increase the output and efficiency. - Longer Service Life

Utilizing wear-resistant materials for the key parts to prolong the service life - Wider Choice

A variety of pump casing and impeller can meet different requirements of the customers. - Axial Adjustment Structure

Axial adjustment structure makes it free to adjust the clearance between impeller and mechanical seal to ensure equipment operation more reliable.

Advantages

- Spare parts interchangeable with NOV Mission Pump.

- Pump shell and impeller wear-resisting material.

- Open impeller,apply to transport high viscosity drilling liquid.

- Combination seal for a long service life.

Applications

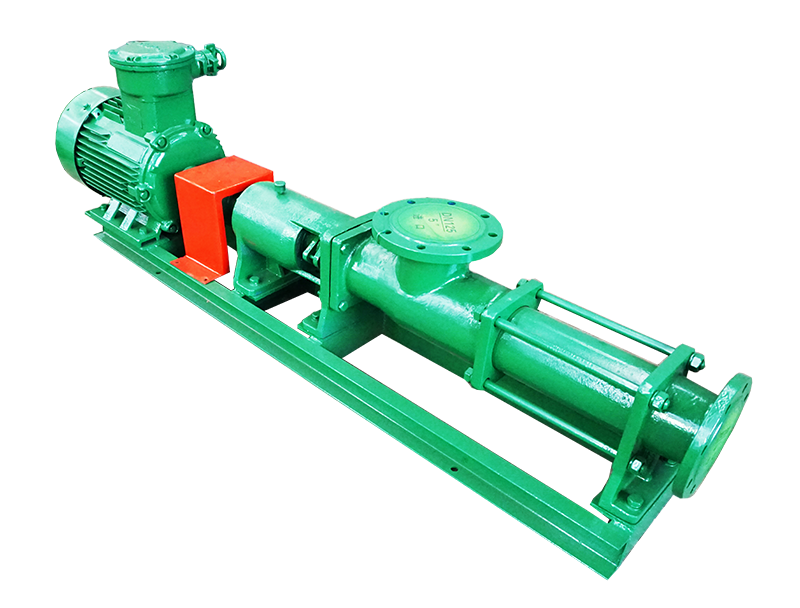

- Drilling Applications

Mud mixing and shearing operations, desanding and desilting, degassing, supercharging, centrifugal feed, mud cooling towers, wash down. - Other Applications

Chemical, refinery, industrial, construction and agricultural applications

Specifications

|

Model |

Power |

Flow |

Lift(m) |

Efficiency |

NPSH |

Electric |

|

TRSB8×6-14 |

75KW |

320m3/h |

40m |

65% |

5 |

50HZ |

|

TRSB8×6-12 |

355m3/h |

43m |

66% |

4.8 |

60HZ |

|

|

TRSB8×6-13 |

55KW |

290m3/h |

33m |

64% |

5.5 |

50HZ |

|

TRSB6×5-12 |

196m3/h |

48m |

61% |

3 |

60HZ |

|

|

TRSB6×5-13 |

45KW |

180m3/h |

34m |

60% |

3 |

50HZ |

|

TRSB5×4-14 |

149m3/h |

61m |

58% |

4.6 |

60HZ |

|

|

TRSB6×5-12 |

37KW |

160m3/h |

30m |

60% |

3 |

50HZ |

|

TRSB5×4-12 |

112m3/h |

45m |

58% |

4.6 |

60HZ |

|

|

TRSB6×5-11 |

30KW |

120m3/h |

21m |

62% |

2.5 |

50HZ |

|

TRSB5×4-12 |

112m3/h |

37m |

57% |

4.6 |

60HZ |

|

|

TRSB5×4-12 |

22KW |

90m3/h |

30m |

56% |

4.5 |

50HZ |

|

TRSB5×4-10 |

105m3/h |

30m |

57% |

4.2 |

60HZ |

|

|

TRSB5x4-11 |

18.5KW |

90m3/h |

24m |

56% |

4.5 |

50HZ |

|

TRSB4x3-12 |

55m3/h |

46m |

48% |

4 |

60HZ |

|

|

TRSB4x3-13 |

15KW |

50m3/h |

40m |

48% |

4.5 |

50HZ |

|

TRSB4x3-11 |

54m3/h |

35m |

47% |

4 |

60HZ |

|

|

TRSB4x3-12 |

11KW |

45m3/h |

30m |

47% |

4 |

50HZ |

|

TRSB3x2-12 |

28m3/h |

45m |

40% |

3.1 |

60HZ |

Write your message here and send it to us